Case Study: How ML‑062211‑P04 Asm-Rear Nest Assembly Restores Ink Metering on Mark Andy 2200 & 4150 Flexo Presses – Milwaukee, WI

Client Overview

A narrow-web converter in the Milwaukee region contacted M&L Machine Tool after struggling to locate a reliable source for Part 062211‑P04 Asm-Nest Rear Assembly. The company runs multiple Mark Andy 2200 & 4150 flexographic presses—key assets in their label and flexible packaging lines. When a nest assembly failed during changeover, production halted. The part wasn’t available from their normal supplier, and each lost day risked thousands in delayed shipments. Avg daily expected losses: $2000/day.

Introduction

Flexographic print shops often operate both Mark Andy 2200 and the upgraded 4150 press models. The 062211‑P04 Asm-Nest Rear Assembly fits both, and maintains precise blade alignment inside the doctor blade assembly. Proper blade angle is necessary for clean ink transfer across the anilox roller. While, consistent metering reduces print defects and keeps presses running without interruption.

Problem Summary

The ML‑062211‑P04 Asm-Nest Rear plays a key role in maintaining the function of the doctor blade system. It locks the rear of the blade at a 25–30° angle against the anilox roller, providing accurate ink metering and uniform print density. Without proper seating and pressure, the blade will chatter or float, leading to print streaking, edge slur, or even damage to expensive anilox rollers.

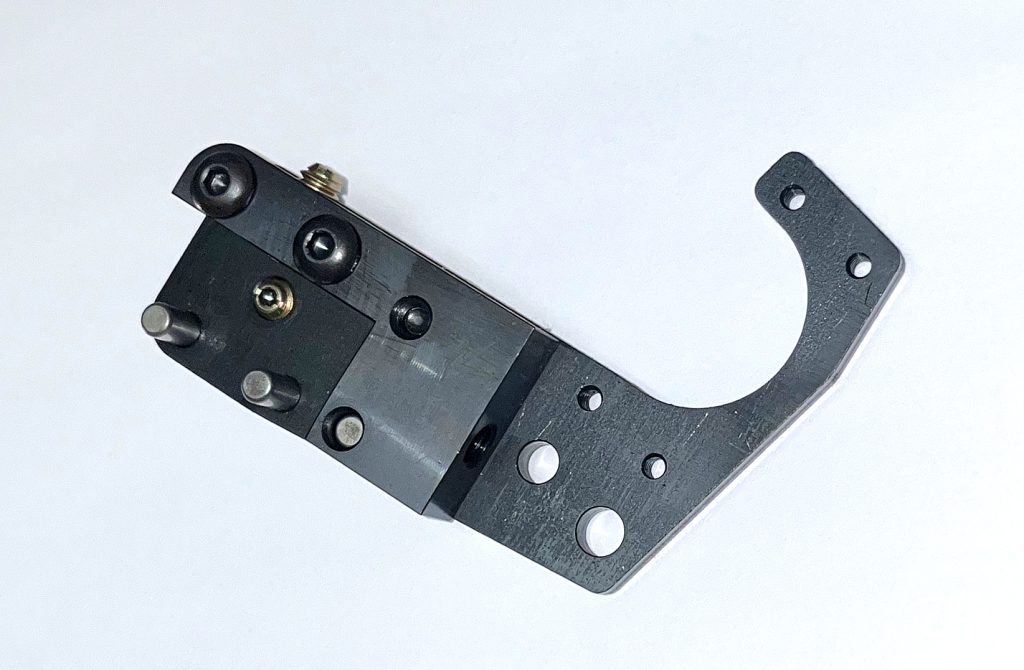

The ML 062211-P04 Asm-Next Rear part is precisely reverse-engineered rear nest holder used within the doctor blade assembly of Mark Andy 2200 and 4150 flexographic presses. The component secures the blade’s angle and pressure to ensure accurate ink metering across the anilox roller.

Even though the nest appears simple, it must be precision machined. Tolerances of ±0.002” and surface finishes below 32 microinches Ra are needed to maintain consistent contact under 1 Bar of blade pressure.

When a client’s nest fails, it can’t be replaced with a makeshift part—any deviation in fit or angle will compromise print integrity across the full web width.

Solution Overview ML‑062211‑P04 Asm-Nest Rear Benefits

M&L Machine Tool confirmed compatibility with Mark Andy 2200 and 4150 series presses and can ship immediately, since the part exists within the M&L in stock catalog. Installation was completed in less than 48 hours using proper torque sequence. No modifications or rework required.

The hardened steel ML‑062211‑P04 Asm-Nest Rear Holder Restores Ink Metering includes OEM-level dimensional tolerances and surface finishing, helping it seat securely while resisting wear from daily cleaning, solvent exposure, and blade replacements. Because the client was already scheduling routine flexo press maintenance, the install took place during their planned downtime, minimizing interruption.

Results

Press function was fully restored, and print quality met prior standards immediately. The client avoided outsourcing print jobs and has since ordered additional assemblies for their backup press. M&L’s pricing offered up to 50% cost savings compared to OEM-sourced components. This made it cost-effective not only as an emergency replacement part but also as part of a broader maintenance strategy. The buyer has now tagged ML‑062211‑P04 Asm-Nest Rear Holder Restores Ink Metering as a stocked item in their internal inventory tracking system.

M&L’s pricing offered up to 50% cost savings compared to OEM-sourced components. This made it cost-effective not only as an emergency replacement part but also as part of a broader maintenance strategy. The buyer has now tagged ML‑062211‑P04 Asm-Nest Rear Holder Restores Ink Metering as a stocked item in their internal inventory tracking system.

For other converters running Mark Andy 2200 press parts, M&L now maintains regular stock of high-turnover assemblies, including this rear nest. Most parts ship in under 48 hours with no minimum order quantities. Stop The Downtime.

ML‑062211‑P04 Asm-Nest Rear Holder Restores Ink Metering Compatibility and Application Use

- ML‑062211‑P04 Asm-Nest Rear — this is the official MLM listing name.

- ASM, NEST LOADED REAR DR BLD — appears in OEM-style naming conventions and on distributor sites (DR BLD = Doctor Blade).

- Additional references list as:

- “Rear Nest Assembly”

- “Nest Loaded Rear Doctor Blade”

- “Nest Assembly within Doctor Blade System”

The 062211-PO4 Asm-Nest Rear part is not the blade itself, nor the complete blade system.

🔩 It is a nesting/retaining component that positions the doctor blade within the larger ink metering system of the press as part of the doctor blade assembly — but it’s not the doctor blade.

Location

- 📍 Region: Milwaukee, WI

📌 Cross Streets: Hwy 45 & Main Street

🗺️ Lat/Long: 43.5181° N, 88.2224° W

🏭 Industry: Flexographic Label & Packaging

🧭 Landmarks: Kewaskum Industrial Zone, Milwaukee River Parkway

M&L’s parts are trusted by high-volume production teams who can’t afford downtime. Our fast-turn fulfillment and consistent specs help eliminate delays, misfits, and costly rework.

Mark Andy is a trademark of Mark Andy Inc. M&L Machine Tool is not affiliated with or endorsed by Mark Andy. Our parts are aftermarket replacements, designed and manufactured by M&L Machine Tool to meet or exceed OEM specifications — from 30% to 50% cost savings over original parts.