Case Studies – M&L OEM Quality Replacement Parts

Case Study: OEM-Quality ML‑062211‑P04 Nest Holder Restored Ink Control on Mark Andy 2200 & 4150 Flexo Presses

📍Milwaukee, WI

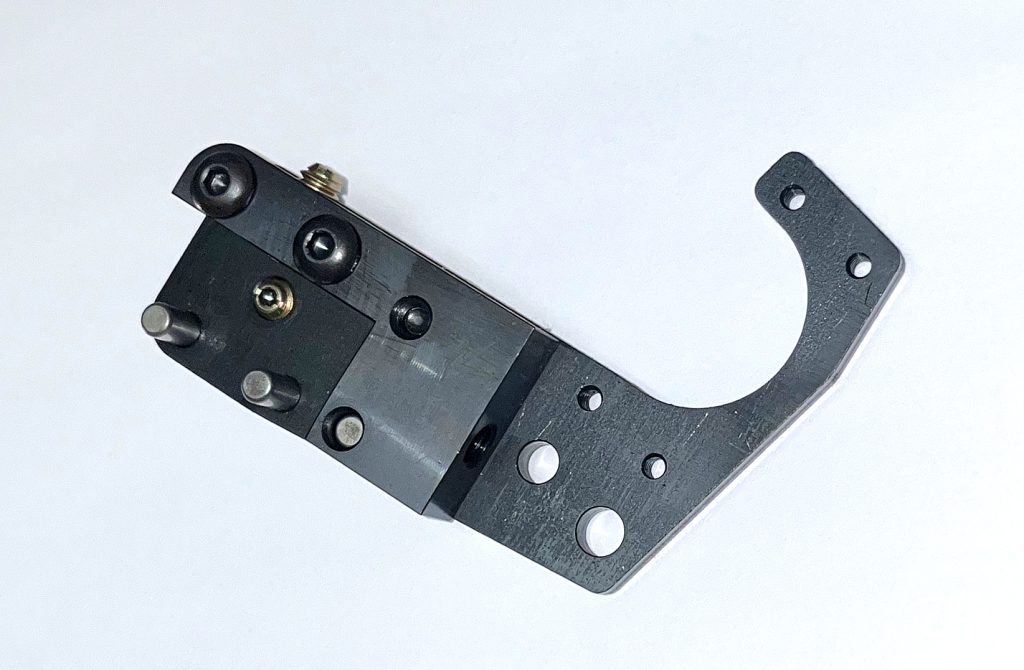

The ML‑062211‑P04 Asm-Nest Rear plays a key role in maintaining the function of the doctor blade system. When a nest assembly failed during changeover, production halted. Avg daily expected losses: $2000/day.

Case Study: OEM Quality Chain Lugs and Pushers Improve Stitcher Line Performance in Chicago, IL

📍Chicago, IL

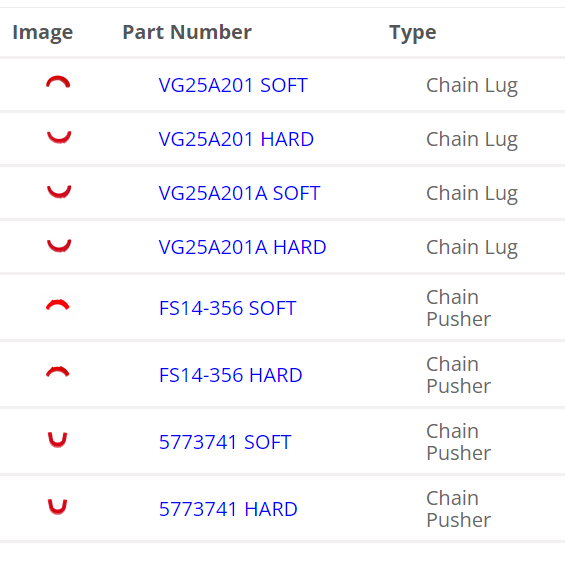

Precision-engineered from high-performance urethane, M&L’s chain lugs and pushers withstand the continuous motion and impact of commercial stitcher chains.

Case Study: How FS14-356 SOFT Chain Pushers Reliably Solved Feed Issues on Stitcher Models SP705, SP750, SP855, SP1000, SP1100 – Chicago, IL

📍Chicago, IL

M&L Machine Tool engineered the FS14-356 SOFT Chain Pusher s with reverse-engineered tolerances and a thermoset polyurethane body are tested for ASTM D-395 compliance.

Case Study: How Part #3121056 – Profold Bearing Block Assembly Reduced Downtime in Phoenix, AZ Mail Processing

📍Phoenix, AZ

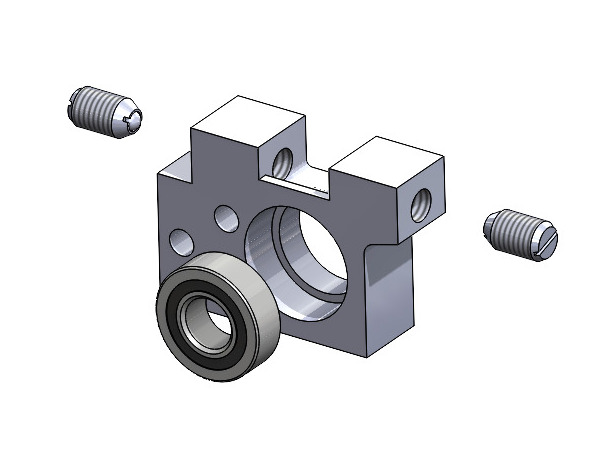

By switching to M&L Machine Tool’s Part #3121056 – Profold Bearing Block Assembly, the Phoenix facility immediately reduced maintenance costs by 50% per replacement. Fast 48-hour part delivery minimized downtime. Avg daily expected losses: $2500/day.

Case Study: How a Minneapolis Printer Saves Over $5,000 on Muller Martini 0316.2353.3

📍Minneapolis, MN

The OEM cam wasn’t just expensive — it was holding up the entire finishing process. The customer needed the replacement cam Muller Martini 0316.2353.3 fast, but couldn’t afford the price or the delay. Waiting weeks wasn’t an option. Here’s how M&L Machine Tool helped STOP THE DOWNTIME.